Originally posted by Stock

View Post

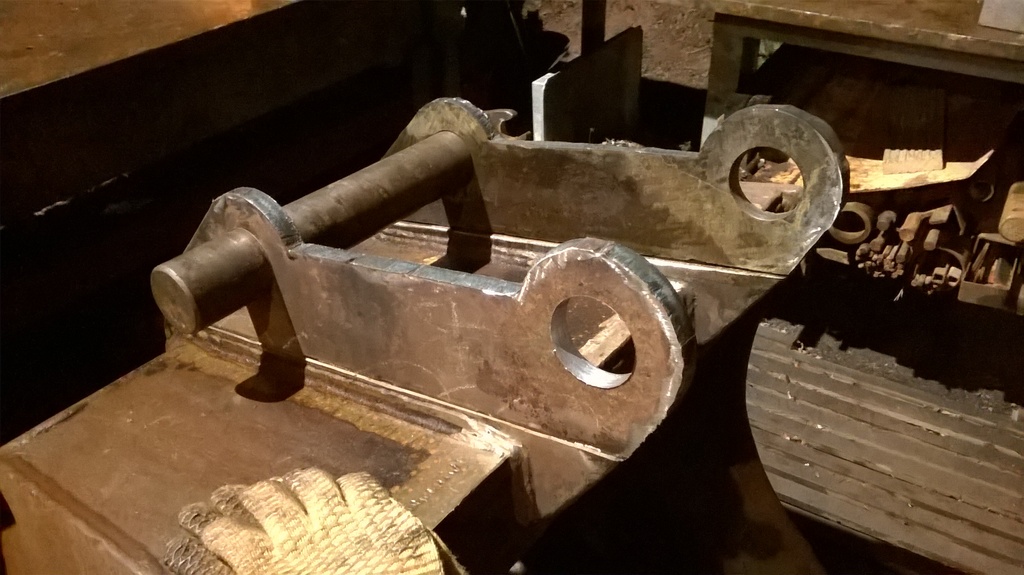

Know where you're coming from Stock, but this is one nearly new condition bucket and'd be a shame to hack it about.

One of the guys on Maskinisten put up a link for me, for what look like the right ones, but haven't had a reply yet - must chase 'em up

This'd be a virtually invincible bucket suitably toothed!! - built like the proverbial brick crapper

(he did crusher hire and had a couple of 13 ton tracked tools).

(he did crusher hire and had a couple of 13 ton tracked tools).

- axle locks will/won't come off/on, on demand,

- axle locks will/won't come off/on, on demand, legs work when they want,

legs work when they want,.gif) and the odd extra switch

and the odd extra switch  inserted strategically in the offending circuits!

inserted strategically in the offending circuits!

so it's always usable and controllable

so it's always usable and controllable  who'd (at the time) no idea of the issues it caused. He could certainly not have relied on it to do a day's uninterrupted graft!!

who'd (at the time) no idea of the issues it caused. He could certainly not have relied on it to do a day's uninterrupted graft!!

Comment